It is important to the life of your press structure, hydraulic systems and tooling that you maintain bed to ram parallelism. Unfortunately, many operations require production systems that need the press tooling and dies to be loaded off-center. In these cases, symmetrical loading is often inefficient, impractical or even impossible to achieve due to part geometry or production requirements. Additionally, the trend to improve production efficiency and reduce costs is spurring an increase in off-center applications as manufacturers consolidate multiple dies or processes into single machines.

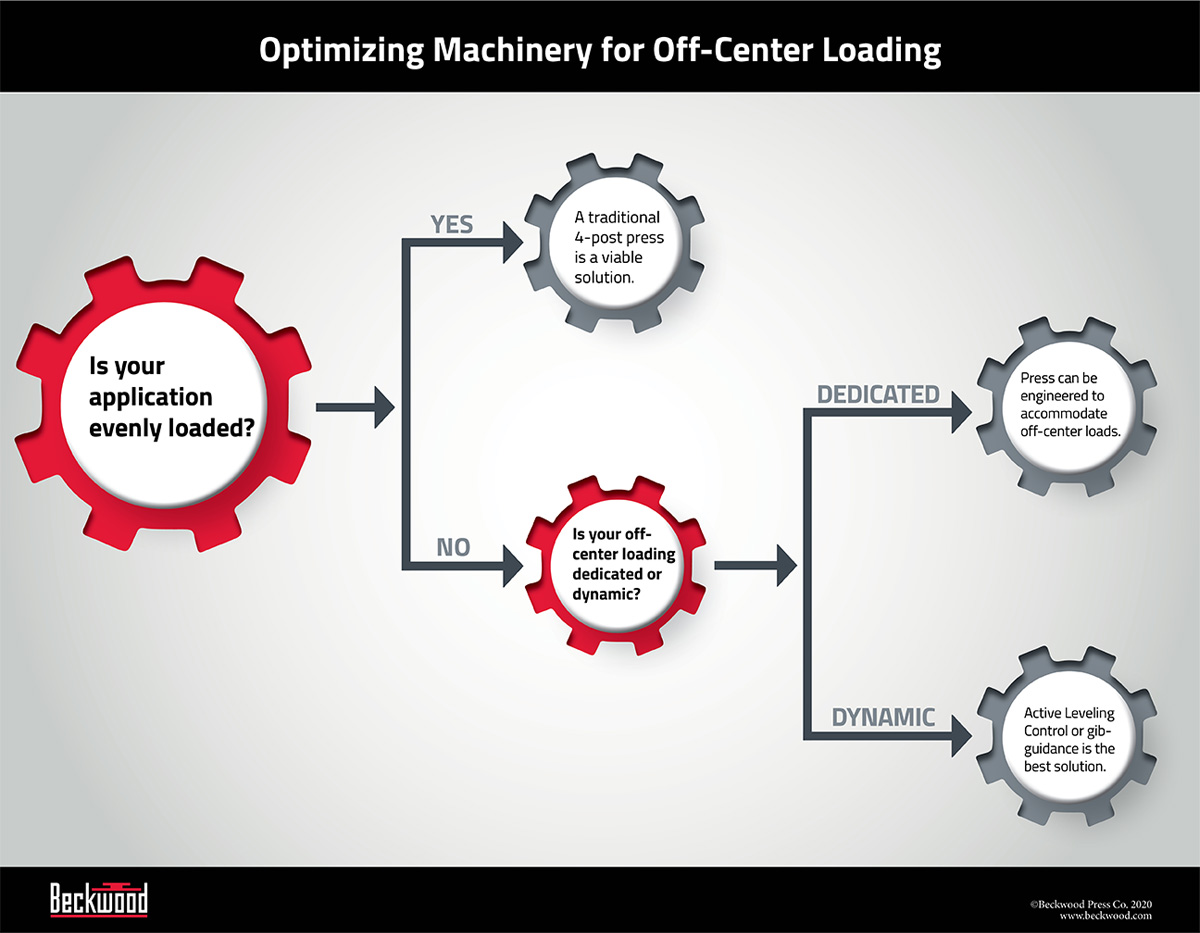

Fortunately, there are ways to counteract the problems associated with off-center loading. By answering the following questions, you can start to determine the best way to overcome any off center loading you may face.

Dynamic Off-Center Loading

Manufacturers looking for a multi-purpose press to run multiple processes with varying load configurations experience Dynamic Loading. This type of off-center loading is best accommodated through the use of a gib-guided hydraulic press or by Beckwood’s proprietary Active Leveling Control System (ALC).

Gib-guided machines combat the off-center load through structural rigidity and a fully adjustable 8-point gib guidance system. As off-center loads are run on the machine, the gibs can be checked and adjusted on a scheduled basis in order to ensure bed to ram parallelism is maintained.

Non gib-guided presses, such as a four-post press, equipped with Beckwood’s ALC include a multi-axis high-speed motion controller, linear transducers to monitor ram position and technologically advanced proportional valves. The motion controller provides closed loop servo control of each individual press cylinder to maintain bed to ram parallelism despite how the press is loaded.

Active Leveling control is offered in either 2 or 4 axis depending on the specific application. Two axis control provides parallelism from left-to-right or front-to-rear, while four axis control provides control of both left-to-right and front-to-rear.

Dedicated Off-Center Loading

In dedicated off-center loading applications, the tooling and loading requirements are known at the time of the press design. This allows the engineers of the machine to compensate for the off-center loading when designing the structure and hydraulic system. Gib-guided or Active Leveling Control (ALC) systems may still be used for dedicated off-center loading applications but may be unnecessary in many cases.

Whether the end user’s application requires dedicated or dynamic off-center loading, Beckwood’s proprietary technologies like Active Leveling Control are available to ensure part quality while reducing die wear and setup time. This technology is transforming what was once considered an obstacle, into a reliable method for meeting your application-specific loading needs.

Consult a Beckwood Engineer about Your Off-Center Loading Issues