Companies around the world rely on Beckwood machinery every day to overcome manufacturing challenges just like yours. From increasing production capacity to eliminating unplanned downtime, Beckwood’s mission is to engineer and build reliable custom hydraulic and servo-electric presses to meet and exceed your requirements and ensure your success. Below are just a few of our manufacturing success stories.

-

Press Repair, Rebuild, & Relocation

A global manufacturer of transformers needed to repair and relocate a 10-year-old press. After only 3 weeks, the customer received a re-built press with several major upgrades to ensure continuous production and reliability for years to come. Read More

-

Triple-Action Press Increases Aerospace Supplier’s Production Capacity by 60% – Weldmac

“At double the tonnage of our other triple-action presses and with a larger bed size, we’ve already increased capabilities by 50%. Ease of use due to programmability should push capabilities to a 60-70% increase.” Marshall Rugg, Weldmac Read More

-

Overcoming Barriers of Entry into Titanium Hot Forming

Learn how Pryer Aerospace overcame the barriers to hot forming titanium and won new aerospace contracts. Read More

-

Versatile Job Shop Increases Capacity with Custom Deep Draw Press – Columbia Metal Spinning

"We chose Beckwood because they they could tailor a press to meet our requirements and handle the different materials we wanted to form," said Ken Kolman, quality manager at Columbia Metal Spinning. Read More

-

Dahlstrom Roll Form Relies on Hydraulic Presses for Speed, Accuracy

“Our presses have functioned accurately and reliably for many years, and our operators like the standardized interface Beckwood works with us to create on each machine." Rob White, President, Dahlstrom Roll Form Read More

-

Aerospace Supplier Cuts Die Change Time from 2 Hours to 10 Minutes

With the Automated Die Storage & Retrieval System, this aerospace customer reduced changeover time from 2 hours to 10 minutes, adding 3.5 hours of production during a typical 8 hr shift. Read More

-

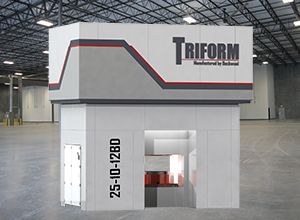

Sheet Hydroforming Takes Flight in Thailand – Jinpao

“The Triform team is very supportive,” said Victor Chung, Managing Director at Jinpao. “Their Sales, Application and Engineering teams are very helpful to a new-entry company in this industry. We ultimately chose Triform because of their total solution.” Read More

-

Hydraulic Press Takes Forming to a New Level – Empire Level

Empire ultimately chose Beckwood because they build highly customized, American-Made machinery that can integrate well with current systems. "That was a deciding factor for us," said Steve Lallensack, Director of Operations at Empire Level. Read More

-

Bulge Forming Rupture Discs – Fike Corporation

With a relationship over a decade strong, Bill Schwagerman, Senior Project Manager- Engineering, of Fike Corporation says: "We're now engaging with a younger generation at Beckwood. It not only feels like the work ethic and quality of technology has been passed down, but we also see them pushing the technology into new territory. As a result, their equipment continues to align with our needs.” Read More

-

Compression Molding – Oak Ridge National Laboratory

“It is our goal to make this lab the intersection of our 3D printing capabilities and composites processing,” said Jesse Smith, Manager of Industrial Partnerships at Oak Ridge National Laboratory. “The new Composites Lab is a showplace for the industry, and Beckwood’s press is an important tool for us.” Read More

-

Rubber Pad Forming Press – Milford Fabricating

“We run anywhere from 30 to 40 different part numbers on the press in a given day,” said Joe Connolly, Operations Manager at Milford. “We estimate we are saving 20% or better in production time for each part.” Read More

-

From Press Brake to Sheet Hydroforming – Steelville Manufacturing

“We had been forming parts for years which we now know were tailor-made for the Triform,” Steelville Engineer Joseph Dust. “The addition of the 24-5FC definitely makes forming those parts much easier. With Triform, the overall time required for the completion of our tools has been cut in half!” Read More

-

7 Presses – An Arsenal of Forming Equipment – Aerospace Manufacturer

“This seven-machine project is a terrific example of Beckwood’s ability to solve our customers’ 360- degree manufacturing challenges,” said Beckwood President, Jeffrey Debus. “Our specific experience with aerospace industry forming applications and diverse engineering and manufacturing capabilities make us an ideal single-source supplier.” Read More

-

Hydraulic Trim Press Helps Eliminate Downtime – Automotive Manufacturer

The Beckwood PPM system is able to recognize acceptable parameters for each metric and notify the user’s team of emerging patterns that could lead to problems...before a shutdown occurs. This type of early detection is paramount for critical path equipment. Read More

-

Hydraulic Multi-Action Deep Draw Press -Meggitt Safety Systems

“Having the strength of Beckwood at our backs, through their proactive support efforts and dedicated service technicians, provided the level of comfort we needed to make this project work. This is not just a piece of equipment; it’s a complete forming solution.” -John Krochmal, Meggitt Safety Systems Read More

-

Triform Fluid Cell Sheet Hydroforming 16-5FC – Piper Aircraft

“We might change tools 15 times or more per shift. With the Triform, tool changes literally take seconds. Conversely, changing tools on our larger hydroforming presses can take 30 minutes or more.” - James Priest, Lead Press Operator Read More

-

Triform Deep Draw Sheet Hydroforming Cuts Tooling Costs

Thanks to the flexible rubber diaphragm in the Triform press, this manufacturer was able to eliminate secondary polishing completely, while slashing tooling costs by 70% and reducing waste. Read More

-

Sheet Hydroforming Eliminates Annealing & Speeds Production – Aerosud Holdings

“With the success we have had with the hydroforming press on the A320 program, Aerosud is now working on the design for the Airbus A350 Slat Track Cans using the press.” - Dr. Leon Labuschagne, Director of Technology for Aerosud Holdings Read More

-

Multi-Ram Press Consolidates Manufacturing Processes – Osmundson Manufacturing

“The size and configuration of the press require less steps and less motion from the operators. The machine’s small size means an operator doesn't have to reach far to run both sides of the press. It’s been a nice upswing for us. The ability to form and fixture-quench the part at the same time has eliminated three steps from our production cycle.” -Doug Bruce, President and Owner, Osmundson Manufacturing Co. Read More

-

Lighting Manufacturer Cuts Production Costs by 70%

Thanks to their new Triform Deep Draw Hydroforming press, our customer no longer needs to stock the expensive molds that had originally been required to cast their products. Their post tops also now have a flawless finish due to the flexible rubber diaphragm which acts as the female half of the tool. As a result, production costs went from approximately $30.00 per piece to $8.00…a savings of more than 70% per piece! Read More

-

From Rubber Pad Forming to Deep Draw Hydroforming: Slash Production Time & Eliminate Wrinkling

Using their Triform deep draw sheet hydroforming press, this manufacturer was able to eliminate spring back, scrap, manual handwork, and wrinkles. The Triform press has automated manufacturing operations so successfully that it's saved a total of 55 minutes in the production of each of these parts. Read More