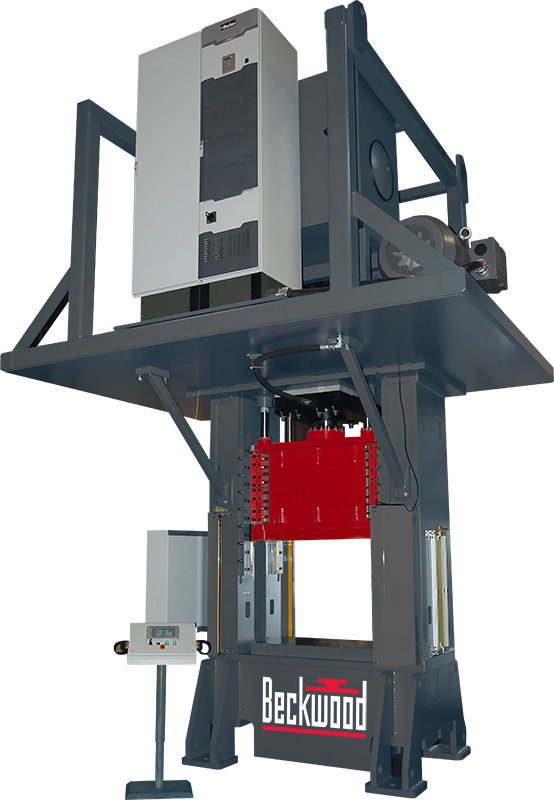

Hydraulic & Servo Press Machines for High Temp Manufacturing

High temperature manufacturing has become an instrumental capability for manufacturers across the aerospace, defense, and automotive sectors. As demands for high strength materials and complex part geometries continue to rise across these industries and more, manufacturers must strike the right balance between robust production and process flexibility. At Beckwood, we empower manufacturers across all industries to tackle their high temperature manufacturing processes with a wide variety of custom hydraulic and servo-electric equipment.

Types Of High Temp Forming:

• High Forming

• Superplastic Forming (SPF)

• Hot Stamping

• Forging

• Powder Compacting

• Compression Molding

Hot Forming

Hot forming is the key to working with high strength metals that are difficult to shape, like titanium. With this revolutionary forming technology, users can produce parts of superior quality with greater precision, all using less tonnage than a traditional press. Hot forming presses use an enclosed, insulated forming area heated by electrical rods that are dispersed across the platen boxes. This configuration allows for precise control over the temperature across every square foot of the forming area for efficient use of heat exactly where you need it most. The high heat contained within the press makes it easier than ever to form complex shapes out of high strength materials with a near-zero risk of cracking, tearing, and other defects that commonly occur during cold forming processes. Worried about safety? With insulated doors and an external control panel, operating a hot forming machine is just as safe as using a regular hydraulic press. Expand your manufacturing capabilities with a custom hydraulic or servo press machine.

Superplastic Forming (SPF)

Similar to hot forming, SPF allows operators to form sheet material within a heated forming area for greater malleability. Unlike hot forming, SPF uses a single, unmated tool, which can help save immensely on associated tooling costs. In place of a mated die, SPF instead uses pressurized argon within the enclosed forming area. The pressure from the argon forms the sheet material to the shape of the tool, allowing for even more complex geometries. SPF machines can also reach higher temperatures than hot forming equipment, making them a suitable tool for working with superalloys.

Discover everything you need to know about

hot forming and SPF in our latest publication,

Beckwood’s Ultimate Guide to Hot Forming.

Discover everything you need to know about

hot forming and SPF in our latest publication,

Beckwood’s Ultimate Guide to Hot Forming.

Hot Stamping

Hot stamping is functionally the inverse to hot forming and SPF. In hot forming and SPF the workpiece is at ambient temperature while the forming area is heated; where in hot stamping, the workpiece is heated and the forming area is at ambient temperature. As a result, this process often requires a higher tonnage to successfully form the material into the desired shape. Once the part is formed, it is then cooled by quenching. This results in a part that is strong, yet brittle with low resistance to fracturing. Our custom hot stamping press and servo press machine options are engineered to best suit the application at hand, with additional features like part knockout and automation integration available for high volume production.

Hydraulic Forge Press Machinery

One of the most longstanding pillars of metalworking, forging is a process that has drastically advanced since its inception many millennia ago. Today, large-scale manufacturers can forge materials with more speed, precision, and repeatability than ever before with modern hydraulic press machinery. Our custom hydraulic forge press machines are tailored to each individual operation, with ample options for each of the following processes:

• Hot Forging

• Cold Forging

• Open Die Forging

• Closed Die Forging

Powder Compacting Presses

Our powder compacting presses are ideal for manufacturing operations where high pressure must be applied across a small forming area, as most commonly seen in the medical industry. Heated platens and extended dwell capabilities make it easy to sinter powders into one coherent object, and additional systems for weighing, dispensing, and leveling can transform a single press into a self-contained work cell. For medical applications, our servo electric press machine technology delivers unrivaled cleanliness by eliminating the need for hydraulic fluid. With optional enhancements like a dynamic bed cushion, multi-action design, and more, no other press manufacturer can customize a powder compacting press to our ability.

Quote a fully-custom, powder compacting

servo press machine today.

Compression Molding Equipment

Beyond powder compacting presses, we also specialize in custom compression molding equipment for forming and molding composite materials. These presses can be equipped with heating elements to form high temperature metal alloys, composites, reinforced plastics, HDPE, UHMW, and more. Our high quality press construction, innovative engineering, and flexible control systems combine to create the highest quality compression molding equipment available on today’s market.