Beckwood developed Active Leveling Control technology as a means for manufacturers to improve part quality, reduce die wear, and help maintain precise bed-to-ram parallelism. This system provides the ideal solution to counteract the effects of off-center loading, eliminate significant breakthrough shock, or uphold superior parallelism across large bed areas.

What is Active Leveling Control?

Active Leveling Control (ALC) is a unique option available on Beckwood hydraulic presses that uses closed-loop control to maintain bed-to-ram parallelism and reduce snap-through shock during the cycle. Presses equipped with ALC use a high-speed motion controller, linear transducers, and proportional control valves to synchronize press actuators. The multi-axis high-speed motion controller provides less than 1-msec control loop time.

Active Leveling Control is offered in either 2- or 4-axis depending on the application. Two-axis control provides either left-to-right or front-to-rear parallelism. For users requiring both left-to-right and front-to-rear parallelism, four-axis control is recommended.

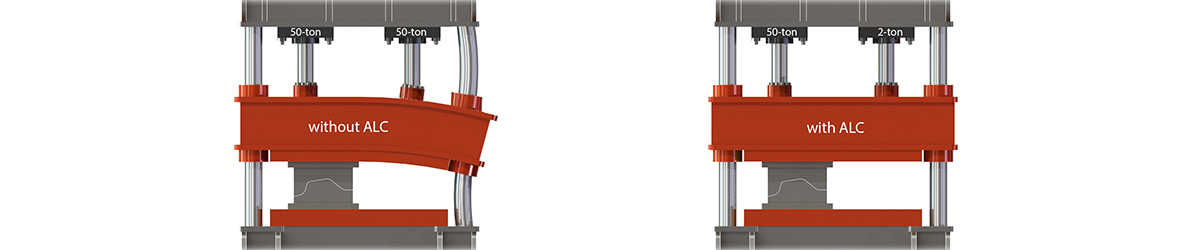

Counteracting Off-Center Loading

Many applications do not apply the load evenly over the press bed which can negatively impact the structural integrity of the machine and tooling; this is often referred to as off-center loading. Challenging off-center loading processes include asymmetrical part geometries, progressive dies or the desire to consolidate multiple operations (and multiple dies) into a single machine. Many presses, particularly those with large beds and/or small tooling, can also be improperly loaded due to operator error, creating additional alignment problems.

Beckwood’s ALC system protects the press structure and tooling while decreasing maintenance costs. Processes that historically could not be accomplished in a traditional 4-post press are now being efficiently and properly executed with the integration of Active Leveling Control. ALC is a cost-effective option for tackling tough applications previously designated only for servo-electric or gib-guided presses.

Minimizing Breakthrough Shock

The tremendous breakthrough shock associated with heavy-duty punching and blanking applications causes challenges which are minimized by Beckwood’s ALC system. The high-speed controller senses the acceleration of the ram during breakthrough and adjusts the axis control valves to restrain the ram, all while remaining parallel. This greatly reduces the effects of the breakthrough shock and improves the life of the press and die.