Enter the Era of The Linear Servo Press

Our signature linear servo press, or LSP™ for short, is carefully engineered to deliver the best in precision, reliability, and cleanliness. Using advanced linear servo press actuation, these machines are capable of exerting up to 500 T of force at a time- greater than any other servo-electric unit on the market. Each press is masterfully crafted at our St. Louis, MO manufacturing facility to guarantee a level of quality that you won’t find anywhere else.

Why Go Servo-Electric?

Servo-electric actuation has allowed the Beckwood engineering team to design and craft the most precise, energy-efficient, and contaminant-free presses that we’ve made to date. Beckwood LSP™ is a new era of servo-electric press technology that combines the flexibility of hydraulic presses with the performance of servo-mechanical presses. Maintenance-free for millions of cycles, LSP™ offers precision, reliability, and efficiency to maximize your production.

We’ve delivered LSP™ presses to satisfied customers in:

• Appliance

• Aerospace

• Automotive

• Aerospace

• Automotive

• Electrical

• Medical

• And many other industries

• Medical

• And many other industries

Whatever it is that you make, there’s an LSP™ model that can find a home in your plant.

Our LSP™ servo-electric presses require hardly any maintenance throughout their entire life cycle, with a BOM that has 70% less components than your average hydraulic press. By eliminating the need for hydraulic pumps, valves, hoses, and filtration systems, businesses like yours can do more of what you do best by keeping maintenance-related downtime to a minimum.

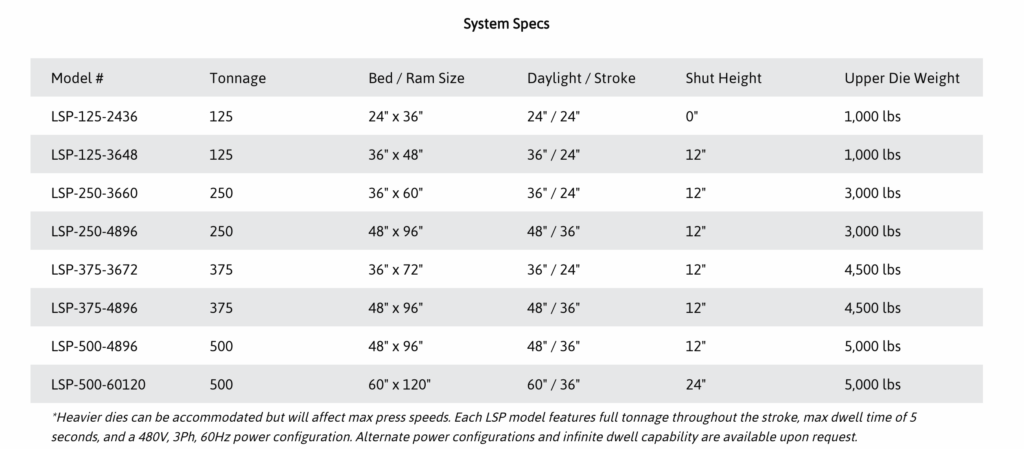

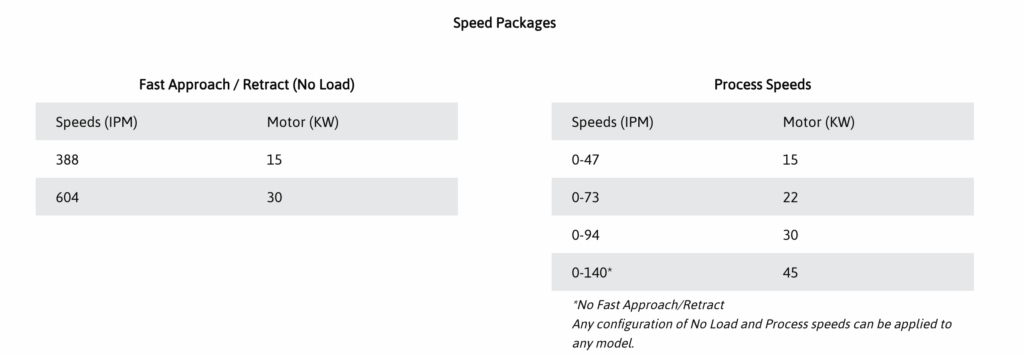

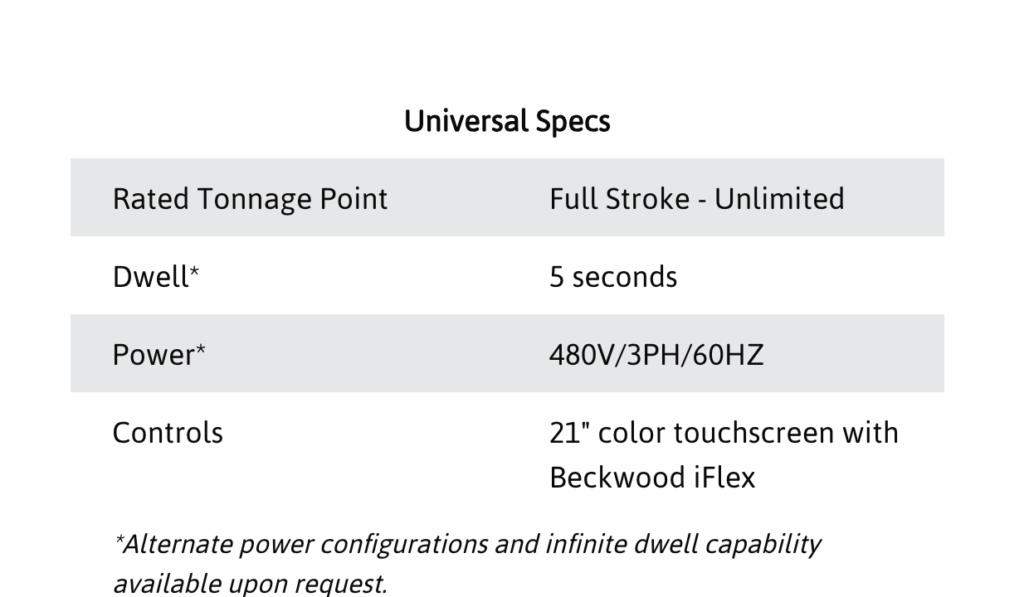

LSP™ Machine Specifications

Unparalleled Forming Precision

The Beckwood LSP™ product line features 8 standard models in an array of sizes, speeds, and tonnages. With presses ranging from 125 to 500 tons, Beckwood LSP™ offers the highest tonnage capacity of any linear servo press available.

Our Most Advanced HMI Software Yet

Our servo-electric models (both EVOx™ and LSP™) are equipped with our most advanced HMI software to make using your new press both easy and exciting.

Enjoy features like:

• Built-in “Go / No Go” Monitoring capability

• High-speed data capture and real-time display

• Performance analysis tools to review current & previous cycles

• Step by Step Recipe Creation & Seamless Recipe Storage Capabilities

• Built-in “Go / No Go” Monitoring capability

• High-speed data capture and real-time display

• Performance analysis tools to review current & previous cycles

• Step by Step Recipe Creation & Seamless Recipe Storage Capabilities

NEED CUSTOM CAPABILITIES?

LSP™ linear servo presses can be equipped with custom features to

tackle your toughest forming challenges with ease.

tackle your toughest forming challenges with ease.

• Compression Molding

• Deep Draw

• Custom Blanking / Stamping

• Hot Forming / SPF

• Deep Draw

• Custom Blanking / Stamping

• Hot Forming / SPF

• Powder Compaction

• Work cell integration

• Automation

• Work cell integration

• Automation

Expect more from your presses.

EVOx –

Low Tonnage

All-Electric Presses

SEE BECKWOOD L SP.

LIN ACTION

LIN ACTION

QUOTE A LINEAR

SERVO PRESS.

SERVO PRESS.