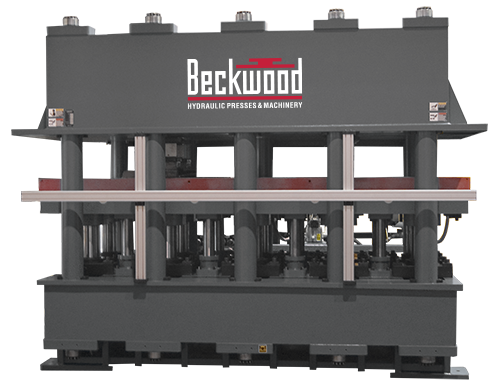

St. Louis, MO – Beckwood recently delivered a unique 10-post hydraulic heated platen press for use in a compression molding application to form honeycomb panels for a variety of industries.

The 10-post design significantly reduced the structural span of the press, allowing the overall height to be minimized while maintaining Infinite Life classification for structural integrity. Without the additional posts, the height of the weldments would have been dramatically to withstand the deflection associated with the high tonnage. The multi-post design results in a 1,000 ton, up-acting press that maintains an optimal working height without the need for a pit or working platform.

Five (5) zones of force control are also integrated into the design, along with photographic ‘eyes’ for part presence identification. The required working-surface varies depending on the size of the honeycomb panel being run. The photographic sensors identify the zones required for the loaded part and activate those areas of the press automatically. This, along with a pneumatically actuated quick die change (QDC) roller system, minimizes the manual requirements of the operator to increase overall production.

Learn more about our non-traditional press options