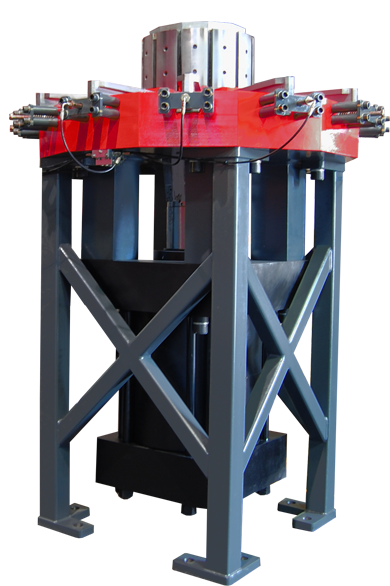

St. Louis, MO – Beckwood Press Company, a leading manufacturer of custom hydraulic and servo-electric presses, has expanded its Triform product line with the addition of hydraulic ring expanders. The machines, which are used to form strong, symmetrical, ring-shaped parts, are commonly used in the aerospace industry to build turbine engines. The ring expansion process helps minimize material thinning and virtually eliminates the stress point issues associated with traditional rolling and machining of rings made from a variety of high-strength materials including Inconel, Hastelloy, and Titanium, among others.

Ring expander specifications including jaw diameter, jaw height, jaw travel, and tonnage capacity can be tailored to the user’s unique specifications. Additionally, Triform ring expanders boast precision programmability and recipe functionality via an Allen Bradley controls platform.

The structure of each Triform ring expander is engineered for Infinite Life using finite element analysis design software. Thus, they can withstand the high forming and surface forces generated during the ring expansion process.

“Beckwood excels at designing forming equipment specifically for the aerospace industry,” said Beckwood president, Jeffrey Debus. “Our ability to provide hot forming presses, sheet hydroforming presses, stretch forming machines, joggle presses, and ring expanders minimizes sub-tier supplier issues and gives our customers a single-source for long-term support.”

Learn more about Triform’s specialty forming equipment