St. Louis, MO – Beckwood Press Company, a leading manufacturer of custom hydraulic and servo-electric presses and automation equipment, has expanded its Triform product line with the addition of extrusion and sheet stretch forming machines.

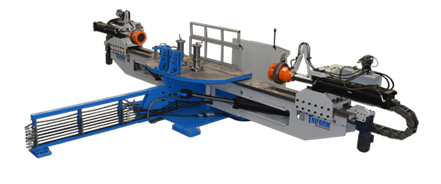

In late 2014, Triform will deliver two (2) 20-ton extrusion stretch machines, which can accept a maximum part length of 240”. The twin machines feature precision CNC controls, including independent arm movement for increased capability. Integrated tool heating is included to facilitate forming high-strength materials, and full process programmability, with built-in recipe functionality / job storage, is also incorporated.Triform’s stretch forming solutions result in highly accurate forming results, with adjustable cycles to facilitate both traditional and tangential stretch forming.

Triform, is an official representative for ESI, the maker of Pam-Stamp Forming Simulation Software, and offers the suite as an option with each stretch forming system. Pam-Stamp provides advanced simulation capabilities to a variety of manufacturing processes, including stretch forming.

“Expanding our Triform product line to include stretch forming machines allows us to better cater to aerospace customers,” said Beckwood president, Jeffrey Debus. “Modern operations can benefit greatly from a single-source supplier, and aerospace part manufacturers are discovering the advantages we provide.”