St. Louis, MO – Beckwood Press Company, a leading manufacturer of custom hydraulic and servo-electric presses, automation systems, and the Triform line of precision forming equipment, was recently awarded a contract to design and build two custom hydraulic presses for medical contract manufacturer, WHK BioSystems.

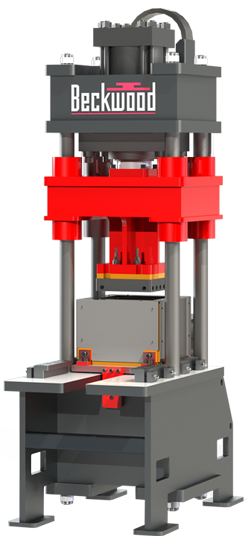

The first press is a 110-ton 4-post compression molding machine which will be used for R&D. It features 12”x12” heated platens with a bed shuttle that includes a heated mold. The second is a larger 1650-ton compression molding press which will be used for production of UHMW sheets. It features 36” x 60” heated platens and a hydraulically-actuated bed shuttle which also includes a heated mold.

Both machines will feature hot oil heating systems with temperature capacities up to 500-deg. F. and temperature tolerances to within +/-5-deg. F. They also include custom mold frames with heaters as well as Beckwood’s proprietary PressLink remote support module for fast, easy troubleshooting.

“Over the last five years, we’ve seen a dramatic increase in demand for machinery to produce UHMW as its use expanded into the medical, aerospace, and defense sectors,” said Caleb Dixon, sales engineer at Beckwood. “In response to this need, Beckwood has developed multiple press systems that are optimal for manufacturing UHMW sheets.”

“In order to mitigate lead times and contamination risks associated with the implant materials supply chain, we made the decision to bring UHMW sheet manufacturing in-house within our own Class 7 cleanroom environment,” said Robert Klingel, Jr., President of WHK BioSystems. “With so few manufacturers capable of creating UHMW components for implantable medical devices, we saw this as an opportunity to add to our list of growing capabilities for the medical and life science communities.”

About WHK Biosystems

Established in 2012, WHK BioSystems is a contract manufacturer of single-use process components and assemblies for the biopharmaceutical, life sciences, and medical industries. They are an FDA registered facility and maintain an ISO 13485:2016 certified quality management system. WHK also offers Class 7 cleanrooms and controlled environment production. Headquartered in Clearwater, FL, they offer a wide array of manufacturing capabilities including TPE and silicone injection molding, TPE extrusion, laser cutting, machining, assembly, 3D printing, and RF welding. Learn more at whkbiosystems.com.