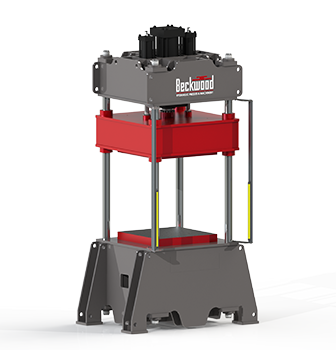

St. Louis, MO – Columbia Metal Spinning, a leader in the production of precision metal spun and deep drawn parts, has awarded Beckwood Press Company a contract to produce a custom 450-ton multi-action hydraulic deep draw press. Scheduled for completion in August 2017, the technologically-advanced machinery will expand Columbia Metal Spinning’s large-diameter draw forming capabilities and supplement their existing 250-ton hydraulic press.

With a 54-in. x 54-in. forming area and a 120-ton hydraulic bed cushion, the new press will be optimal for Columbia Metal Spinning’s deep draw operations. Using a proportional control valve for dynamic control through four different travel zones, the bed cushion applies the resistance necessary to draw the blank material around the tool with ease, reducing wrinkling and guaranteeing optimal material flow throughout the cycle.

Since part quality and repeatability are critical in Columbia Metal Spinning’s job shop environment, Beckwood engineers will develop an intuitive controls system that operates in both manual and semi-automatic modes. Using dual linear and pressure transducers for position and pressure feedback, operators will be able to store and recall part recipes with ease.

To meet Beckwood’s rigorous quality standards, the press structure will be designed to the Infinite Life classification using Finite Element Analysis (FEA) software. The computer-aided simulation, which mirrors real-world manufacturing stresses, ensures the press is robust enough to handle the most taxing applications. Additionally, Beckwood’s proprietary PressLinkTM Remote Connect Module will be included to offer fast, complimentary support and troubleshooting and facilitate program updates without the need for an on-site service visit.

“Beckwood’s reputation and reliability were two key factors throughout the decision-making process,” says Fred Haberkamp, President of Columbia Metal Spinning. “After contacting several referrals, it became obvious that Beckwood is committed to engineering and real-time support of their equipment. Repeat orders tell the story that Beckwood is there for the long haul. More importantly, their presses are made in the USA which means components are standard, off-the-shelf, and readily available. This, combined with the PressLink communications module, ensures that our equipment is easy to maintain and well-supported.”

About Columbia Metal Spinning

Columbia Metal Spinning provides precision metal products (hemispheres, cones, housings, and cups) to customers across a variety of industries including aerospace, automotive, and oil & gas. Using the latest technologies in metal stamping, deep drawing, CNC machining, and PNC automatic spinning, Columbia Metal Spinning is able to provide cost-effective, high-quality solutions to meet their customer’s needs.