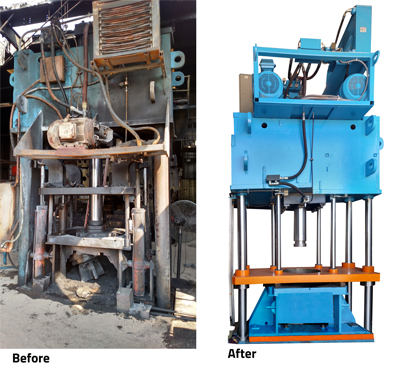

With routine maintenance, a well-built press structure can last generations. A press’ hydraulic & electrical systems, however, will become outdated over time, and may be associated with decreasing reliability as they age. Obsolete hydraulic and electrical systems can pose certain disadvantages beyond press downtime. Press performance, operating flexibility and safety can all be affected by such critical systems that are past their prime.

Beckwood’s hydraulic and electrical system retrofits leverage modern components to increase machine capability. Hydraulic and electrical upgrades present opportunities for enhancing press safety through, for example, the addition of valving configurations or ancillary safety devices for point-of-operation guarding. Rebuilding or replacing antiquated electrical systems can facilitate new HMI/Controls features, such as programmable cycle parameters and alpha-numeric job storage & recipe handling. New components from reputable suppliers like Parker, Rexroth and Allen Bradley feature factory warranties, minimizing downtime and extending the life of your press for the next generation.

Contact our Service Team for a hydraulic & electrical assessment