A bed cushion is commonly required in draw-forming applications to apply resistance force when pushed upon. On a conventional deep draw press, the bed cushion typically has a maximum tonnage that’s one-third the total tonnage capacity of the press and maintains equal tonnage throughout the stroke. This fixed tonnage results in deep draw parts with wrinkles and tears.

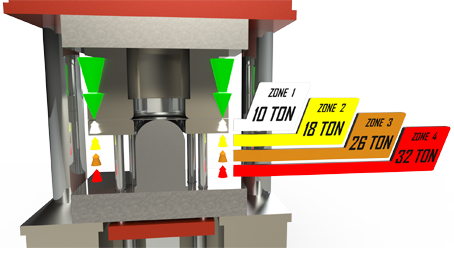

Beckwood’s proprietary Dynamic Cushion Control allows for tonnage adjustments throughout the entire draw process at any point during the stroke. Proportional control valves regulate the bed cushion, enabling dynamic control through four different travel zones. By changing the resistance force “on demand” through the HMI, operators can precisely control material flow to eliminate wrinkling and tearing of their deep drawn parts.

While most draw presses are dual-action, Beckwood also offers triple-action draw presses which are ideal for larger drawn parts and traditional tooling. With this configuration, the lower ram can serve either as a knockout for part ejection or as a dynamic bed cushion, depending on tooling requirements.